1 Product application background

Based on the vigorous development of the domestic industrial economy, many products in life have higher and higher requirements for the storage environment. Common moisture damage causes items to become damp, moldy, oxidized, rusted, agglomerated, deteriorated, discolored and loses luster, and machine parts are aging. Poor contact and so on. The traditional dehumidification equipment in the market currently includes dehumidifiers, air conditioners, heating dehumidification rods, condensing dehumidification boxes, desiccant bags (boxes) and other products; their disadvantages are high power consumption, high noise, and frequent water pouring or frequent replacement. Desiccant, there are problems with power failure and humidity return and environmental temperature difference, and it can not accurately control the temperature and humidity in the environment.

In order to solve these problems, we have successfully developed a new electronic storage device, which is a combination of humidity control movement, semiconductor temperature control movement, temperature and humidity controller, etc., which can be changed and accurately controlled in the environment. Temperature and humidity system; adopts micro-motor drive, low power consumption, no noise, no need to pour water or replace desiccant, have functions such as dehumidification or humidification, heating or cooling in the environment, and computer storage memory function will not be affected by power failure Loss of setting parameters, power on automatically start operation, precise temperature and humidity control, temperature and humidity control error ± 3%, extremely safe and reliable to use.

As the company grows, our environmental control related products have formed a complete management system from R&D, production, final inspection to installation and commissioning. The company relies on its strong technical strength, relying on Shenzhen's excellent development environment, adhering to the enterprise spirit of "pioneering and innovative, striving for perfection, honesty and pragmatism", relying on strict quality management, and continuously developing and developing in related fields. Products are widely used in electric power, military, hospitals, enterprises and institutions, optoelectronics, chemical products, precision pneumatic components and other users who need specific storage environments. With advanced technology, cost-effective products and perfect after-sales service, they have won the industry’s Praise and recognition, Ruineng people are willing to continue to cooperate with all sectors of society in good faith, make progress together, and strive to become the most innovative and respected global leader.

2 Product application areas

2.1 Power and electrical safety tools

In the power industry, insulating tools are widely used for live work or operations, and the insulation performance of damp and contaminated insulating tools is reduced, which seriously endangers the lives of operators and maintenance personnel. The safety tools and equipment used by the staff during the maintenance and testing of power generation, transmission, transformation, distribution and electrical equipment, including: insulation safety tools, insulation tools, insulation protection appliances, insulation hand tools, testing and maintenance tools .

There are currently several ways to store insulated tools, one is to use wooden or iron cabinets, and the other is to store and keep the insulated tools in the insulated tool warehouse. Wooden storage racks or tool cabinets do not have a long-term constant moisture-proof effect, are extremely susceptible to moisture, and are difficult to meet the storage requirements of insulated tools. Insulation tool warehouse is to store the insulating tools in an independent warehouse, dry them by heating and dehumidification, and then take them out from the warehouse when they are used. However, due to the large investment in this warehouse, the high energy consumption and the slow drying process, especially for There is no need to build a warehouse for insulating tools in units with fewer insulating tools.

According to the chaotic placement of insulation tool rooms in most substations, the placement requirements of live working tools, and the hidden safety hazards of insulated tools due to the environment, we designed a constant humidity automatic control insulation tool. cabinet. Avoid insulation safety tools in power plants or substations from being affected by moisture, deterioration, and dry cracks that affect the performance of storage devices.

2.2 Equipment spare parts and accessories storage

Used for storage and classification management of equipment spare parts, precision accessories, electronic devices, integrated circuit boards, microcomputer chips, advanced lenses, photographic equipment, optical equipment and other electronic materials and accessories to prevent mold, fog, oxidation, corrosion, deformation, Aging fracture, electronic device failure, etc.

2.3 Storage of nutrition, medicine and chemical products

It is mainly used for the storage of raw materials and finished products of nutrition, medicine, chemical products, to avoid moisture absorption and moisture affecting its performance.

2.4 Test instrumentation

It can be used for constant humidity storage of various electric test, electronic test, optical test and test instruments.

2.5 Optoelectronic materials and components and SMT surface mount

Optoelectronic materials and components, optical information (information) industry, optical communication industry, optoelectronic display, laser and laser applications, optoelectronic equipment and electronic components, semiconductor industry, constant humidity storage of integrated circuit surface mount (SMT) before SMT surface mount, After the liquid crystal glass substrate is cleaned, normal temperature water molecules absorb moisture and dry, and the crystal wafers and the adhesives of electrode materials are stored under constant humidity. Constant humidity before encapsulation of multilayer printed wiring board, constant humidity storage after encapsulation and before power-on. Moisture-proof storage of the semi-finished products in the packaging After single-sided packaging, oxidation prevention and constant humidity storage between the next process.

2.6 Other

Prevent the oxidation (corrosion) of the parts, and keep the parts clean and carry out the safe storage of constant humidity and dust. The precision molds and tools are protected from damp oxidation and safe constant humidity storage to avoid changes in error values.

3 Product control principle

3.1 Three common principles of traditional dehumidification

1) Heating and dehumidification technology: The method of using a heater to heat the air with an electric heater, using an aluminum alloy radiator to dissipate heat, and the principle of external heat exchange to dry the air in a certain space. This method has high requirements for components, Need high power, easy to add tide.

2) Compression condensation dehumidification: The close relationship between relative humidity and air temperature is used to reduce the local air temperature, so that the water vapor in the local air is released and condensed into water droplets due to condensation, which is then exported to the space, and then the air The temperature returns to the temperature before cooling, so as to reduce the relative humidity at the temperature; this kind of dehumidifier has higher efficiency and fast dehumidification, but the minimum humidity is very unsatisfactory. At 25℃, it can only reach 40 %, the energy consumption is also large, because the compressor or refrigeration device must be used to work, and the fan that causes the air to flow continuously are all energy-consuming electrical appliances, and the noise is also large.

3) Nitrogen dehumidification: Use dry industrial nitrogen to fill a confined space, which can quickly reduce humidity. The advantage is that the humidity decreases quickly, but the disadvantage is that a series of equipment conditions such as a nitrogen bottle pressure reducing valve are required, and the cost is also high. This is a category with consumables.

3.2 The principle of effective new technology molecular sieve dehumidification

The new effective dehumidification technology is to use the solid desiccant molecular sieve to have a great affinity for water molecules in the air. It can absorb the water molecules in the air inside the cabinet for a long time until the molecular sieve is saturated, and then the molecular sieve enters the regeneration state through automatic control. After the molecular sieve releases moisture to the outside of the cabinet (the dehydration regeneration rate is very high), it returns to the dehumidification state inside the cabinet, so that the cycle is repeated, and the humidity inside the cabinet can be reduced to the set value; and the humidification function is correct The molecular sieve heats the cabinet intermittently to regenerate and dehumidify, so that the increase of humidity is a controllable process, so that the humidity inside the cabinet can be accurately controlled. The regeneration times of the solid desiccant molecular sieve are relatively long.

For the process control of moisture absorption and dehumidification, the memory alloy spring is used as the operating element. When the solid desiccant molecular sieve is regenerated, the residual heat of the heating element is used to drive the memory alloy spring to act, and the air door baffle is opened and closed. The structure is simple, and the state of moisture absorption and dehumidification can be flexibly controlled.

From the perspective of energy saving in our design, we fully consider the design of heat insulation and heat dissipation, make full use of energy, can accurately and quickly control the working state of the system, and cooperate with the control of the precise sensor electronic digital circuit to form a set of fast regeneration , A green humidity control system with uniform dehumidification, short cycle and precise humidity control.

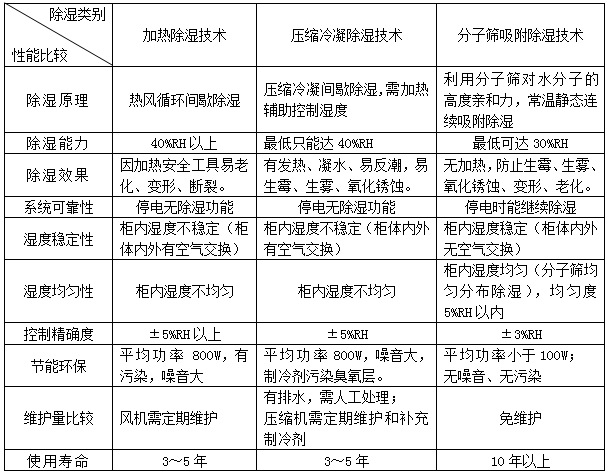

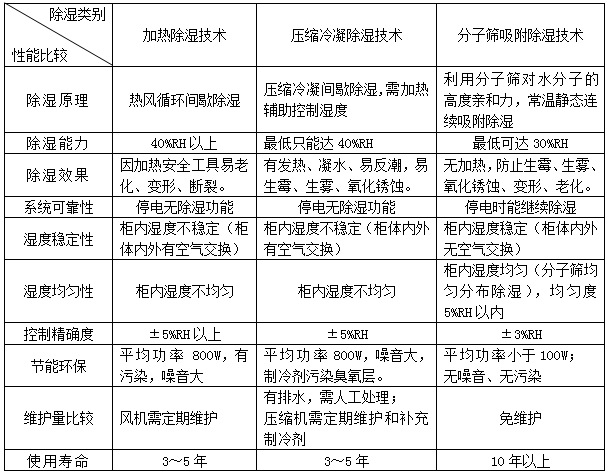

3.3 Comparison of several different dehumidification principles

4 Product technical parameters

4.1 Working environment

Ambient temperature: -20℃~55℃

Environmental humidity: not more than 95%RH

Atmospheric pressure: 80~110KPa

Altitude: not more than 2500 meters

4.2 Product parameters

Temperature range: -20℃~55℃ error value ≤±2℃

Humidity range: 5%RH~95%RH error value ≤±3%RH

Humidity control range: 25%RH~85%RH error value ≤±3%RH

Noise: None

Average power: less than 100W

Service life: more than 10 years

Insulation withstand voltage: the insulation resistance of the power circuit to the cabinet is ≥10MΩ;

Power frequency withstand voltage of 2KV lasted one minute without breakdown.

Power source: 90V~264V AC 50Hz

5 Product features

5.1 Control system

1) Microcomputer control, intelligent storage and memory, setting parameters will not be lost due to power failure, and the device will automatically start to resume normal operation after power on again;

2) Imported sensors to collect data;

3) LED digital tube two-digit display,

4) The function keys on the control panel can freely set the temperature and humidity parameters

5.2 humidity control execution module

Using active molecular sieve X13 particles as the main component, it has strong chemical stability, high adsorption capacity and sufficient mechanical strength, and high thermal stability. It can be repeatedly heated and regenerated, and the number of regenerations can reach more than 100,000 times. It still has 60% adsorption capacity.

The humidity control execution module is to use the molecular sieve with strong regeneration ability to have high affinity for water molecules in the air, effectively absorb the water molecules in the air inside the cabinet, and then intelligently control the molecular sieve through the microcomputer to enter the heating regeneration, and quickly let the molecular sieve release moisture outside the cabinet Then, it enters the dehumidification state inside the cabinet through the intelligent control of the microcomputer, so that the cycle repeats, and the humidity inside the cabinet can be accurately controlled; and the humidification function is to prevent the cabinet from being too dry, and the molecular sieve is used to intermittently heat the cabinet to regenerate and dehumidify. Therefore, the purpose of accurately controlling the humidity in the cabinet can be achieved through the intelligent strategy of the microcomputer.

5.3 Cabinet structure

1) Double-layer high-quality steel (humidity control cabinet), explosion-proof tempered glass door;

2) Install high-quality Taiwan wear-resistant casters at the bottom of the cabinet;

3) Sealed structure to block air exchange and heat conduction inside and outside the cabinet;

4) The structure of the cabinet is flexible, and the insulating rod can be configured in a variety of personalized configurations such as rotating disk and barrel.

5.4 Other

1) The equipment has low power, energy saving, no consumables, no noise, no pollution and environmental protection.

2) The equipment can achieve magnetic isolation and anti-static treatment.

6 Product order

Product ordering should indicate the product model, quantity, specifications, electrical parameters, and special requirements. Any ambiguity when ordering products should be consulted with our company.

Appendix 1: Intelligent humidity control storage (safety tool) cabinet configuration table

Remarks: If the above size does not meet the usage requirements, it can be customized according to actual needs