The charger characteristic test equipment is fully implemented in accordance with the electric power industry standard "DLT724-2000 Battery DC Power Supply Device Operation and Maintenance Technical Regulations for Power System" and the national standard "GB/T19826-2005 General Technical Conditions and Safety Requirements for DC Power Supply Equipment for Power Engineering" Detecting various parameters such as voltage stabilization accuracy, current stabilization accuracy, ripple coefficient, efficiency, power factor and other parameters of the charging module in the DC power supply system of the substation to meet the daily maintenance and inspection needs of the charging module (rectifier, charging device) of the substation/power plant . Operation practice has proved that with the passage of the DC power supply device's operating time, especially after 1 to 3 years of operation, the technical indicators of the equipment will shift. The common problem is: the indicator of the charging module drops, resulting in voltage regulation accuracy and steady current The accuracy and ripple coefficient exceed the standard and the battery capacity decreases. At the same time, on-site inspection personnel do not have corresponding inspection equipment, and cannot find and solve the above-mentioned problems in time. In the long term, the entire DC system will fail or be damaged in advance, directly threatening the safe operation of the power grid.

The charger characteristic test equipment adjusts the input AC voltage of the DC power supply system, controls the output load according to the standard, and automatically collects multiple signals. It forms a movable automatic monitoring device with the industrial control computer, and performs the technical indicators of the DC power system according to the standard. Comprehensive testing. It can automatically generate test reports on voltage stabilization accuracy, ripple coefficient, current stabilization accuracy, efficiency, power factor, etc. to facilitate user management.

Main features

1. Test items:

(1) Measurement of voltage stabilization accuracy

(2) Steady current accuracy measurement

(3) Limiting pressure characteristic experiment

(4) Current limiting characteristic experiment

(5) Ripple coefficient measurement

(6) DC current output error measurement

(7) DC voltage output error measurement

(8) Measurement of charger power and efficiency

(9) Power factor measurement

(10) Battery capacity test

2. The test interface is divided into three:

(1) Stabilization accuracy measurement, current limiting characteristic experiment, ripple coefficient measurement, DC voltage output error measurement

(2) Steady current accuracy measurement, voltage limiting characteristic experiment, DC current output error measurement

(3) Charger power, efficiency measurement, power factor measurement, battery test

3. Reference standards:

(1) "DLT724-2000 Battery DC Power Supply Device Operation and Maintenance Technical Regulations for Power System"

(2) "GB/T19826-2005 General Technical Conditions and Safety Requirements for DC Power Supply Equipment in Power Engineering"

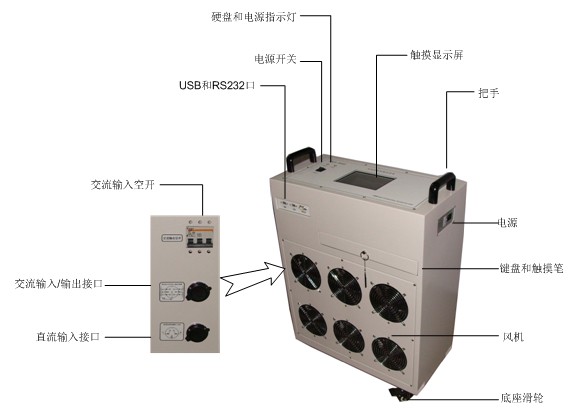

4. The structure of the equipment

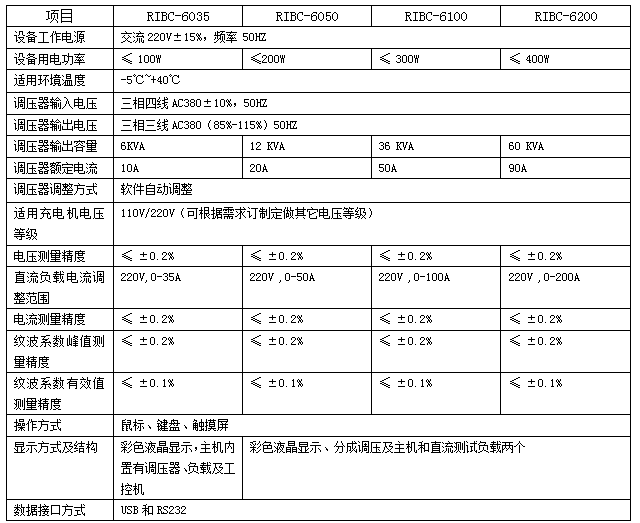

RIBC-6000 input voltage regulation, output load, test host, industrial computer and other components, one device realizes the entire test function, and it is small and easy to move.

5. The industrial computer is used as the operating unit of the equipment, with rich functions, intuitive interface, simple operation, 250G large-capacity high-speed hard disk, and large data storage capacity

6. The operating system of the device is: Windows XP operating system, 1G DDR memory, 8.0-inch touch color LCD screen, full Chinese graphical operation interface, simple and convenient operation.

7. With mouse, keyboard and touch screen, it is easy to operate and powerful.

8. The ripple test uses a high-speed acquisition card with a sampling frequency of 150M, with more than 20 automatic measurement functions and PASS/FAIL Check functions, with fast processing speed, high precision and strong anti-interference ability.

9. The AC test part can test: AC voltage, current, active power, power factor and other parameters with high accuracy.

10. With manual and automatic test modes, the automatic mode can automatically perform multi-point testing according to the programmed program to improve test efficiency.

11. Multiple test procedures can be set, the procedures include: charger AC input voltage point, charger DC output voltage point, charger output current point, DC load current point and other data.

12. In the automatic test mode, the test is performed automatically according to the process selected by the user, and the process is displayed in real time.

13. AC automatic voltage regulation can adjust the input voltage of the charger's grid according to the test requirements. The voltage is continuously adjustable from 85% to 115%, and the voltage is automatically constant.

14. Test line interface: both AC input and output and DC output use wiring tags, and a special quick connector is installed at the back of the test line.

15. After the test is completed, the test report in WORD format is automatically generated, and it is automatically stored on the hard disk, which can be opened for reference at any time, and can be stored directly through the U disk.

16. With RS-232 interface to realize remote control through PC, multiple USB data storage interfaces.

17. Equipped with PC version analysis management software, which can control the equipment, display various data and waveform diagrams, automatically generate, store, edit and print test reports

18. It can be customized according to the power of the charger